Guide to Common Cathode LED Display

Conventional common led display has been through the years, has constituted a stable industry chain, driving the application of led display, with the development of the economy, the market requirements for led display size is getting larger and larger, using conventional led display to splice the large screen will have a lot of power consumption, every year to pay a lot of electricity costs.

LED display using common cathode technology, its energy-saving effect can reach 30% to 75%, greatly reducing the power consumption, and can save a lot of electricity expenses every year. In fact, “common cathode” is not a brand-new technology, some of the industry’s screen enterprises in the early years of “common cathode technology indoor small pitch products” has been widely used in national key projects, and now with the industry chain and technology products continue to mature, stable, as well as cost reduction. Only now, as the industry chain and technology products continue to mature and stabilize, and the cost decreases, it really makes the common cathode rgb led display into the public view.

1. What Is Common Cathode LED Display?

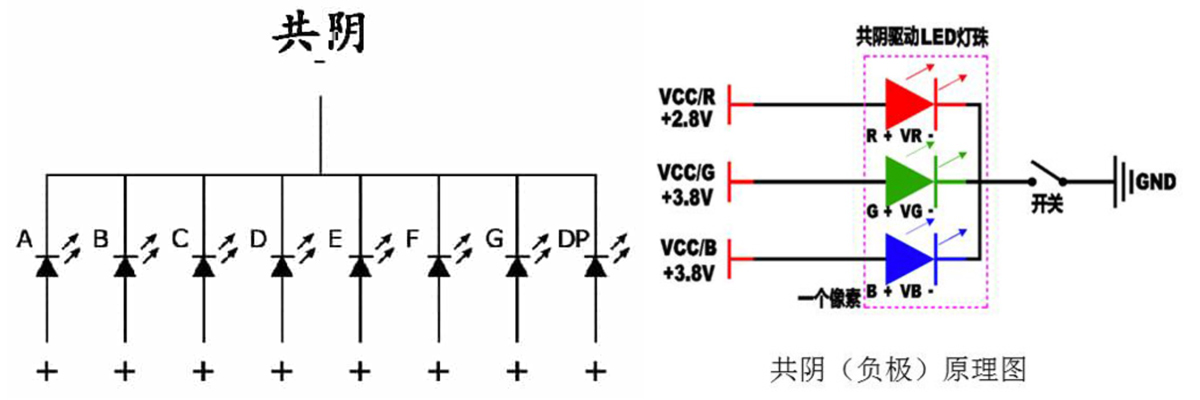

“Common Cathode”, refers to the common cathode power supply, in fact, is a led display energy-saving technology, refers to the use of common cathode way to power the led display, that is, the use of led beads R, G, B (red, green, blue) to separate the power supply, accurate respectively for R, G, B beads to allocate current voltage, due to R, G, B (red, green, blue). G, B (red, green, blue) lamp beads required by the best working voltage and current is not the same, so that the current will first go through the lamp beads and then to the IC cathode, the forward voltage drop will be reduced, the on-state internal resistance will become smaller.

2. Common Anode vs Common Cathode:

- 1). Different Power Supply Method

Common cathode power supply method, as mentioned above, is by the current first through the lamp beads, and then to the IC cathode, so that the forward voltage drop becomes smaller, the conductive internal resistance also becomes smaller.

The common anode connection is the current flowing from the PCB to the lamp beads, to R, G, B (red, green, blue) unified power supply, to incur the circuit forward voltage drop becomes large.

- 2). Different Supply Voltage

Common cathode, as cited above, it will be separate to R, G, B (red, green, blue) to provide current voltage. Red, green, blue three kinds of lamp beads on the voltage request is not the same, red lamp beads voltage request in about 2.5V, blue and green lamp beads voltage request in about 3.8V, so that the power supply can reach the accurate power supply and power consumption is less, led display screen in the work of the heat generated by much lower.

Common anode, is R, G, B (red, green, blue) to give a higher voltage than 3.8V (let’s say 5V) unified power supply, at this time, red, green, blue get the voltage is unified 5V, but red, green, blue the three lamp beads need the best working voltage is much lower than 5V, according to the power formula P = UI, in the case of constant current, the higher the voltage, the higher the power, that is, power consumption The greater, while the led display in the work of the product will also be more heat.

3. Common Cathode LED Display Features:

- 1). Independent Power Supply Energy-saving

Common cathode drive architecture using precise electronic control, based on led red, green, blue three different photoelectric characteristics, with common cathode IC control system and independent private mode, for the led drive circuit precision distribution of different voltage, so that the product power consumption relative to similar products more energy efficient, more power saving.

- 2). Lower Heat

Through the above comparison of common cathode and common anode power supply methods, we know that common cathode configuration led display uses much less power than common anode led display, however, common cathode led display has much lower heat than conventional common anode led display.

LED module partial will use aluminum chassis design, the heat on the PCB board directly through the aluminum heat transfer, the heat generated by the light-emitting chip and driver IC through the aluminum chassis directly outward heat dissipation, small thermal resistance, large heat transfer area, the entire aluminum chassis are led chip heat sink, the bottom shell is made of die-casting aluminum alloy, led display flatness and consistency is also greatly improved, and to ensure the product hardness and strength of the premise of reducing product weight, saving information.

- 3). Color True and More Stable

Common cathode driveway can accurately control the voltage, in reducing power consumption at the same time, more reduce the heat, continuous work under the wavelength without drift, stable display of real color.

- 4). Screen Life Enhancement

Common cathode screen energy consumption is reduced, thus significantly reducing the temperature rise of the system, effectively reducing the probability of led damage, improve the stability and reliability of the entire display system, and more effectively extend the life of the system.

4. Advantages of Common Cathode LED Display:

In recent years, as led displays gradually enter a mature stage, the requirements for products are getting higher and higher, especially in terms of reliability, service life and display consistency of the claims continue to rise, common cathode energy-saving technology occupies an advantage in these aspects.

It can reduce the red led supply voltage to reduce system power consumption, reduce the screen temperature, so that the electronic components in a relatively low temperature with higher reliability, longer life, more advantageous in ultra-small pitch and Mini/Micro led applications. At the same time, the integration of other energy-saving technologies can be more effective in maximizing energy savings.

LED display energy saving has always been the focus of industry-wide attention, especially for the “power consumption” of the outdoor fixed led display owners, because of its long-term use, energy saving allows customers to save costs, but also more in line with the development needs of the environment, the long-term is more cost-effective.

Common cathode energy-saving screen temperature than conventional screens to reduce 30-50%, effective control of temperature rise, screen operation more stable; power saving of about 30-50%, energy efficient drive IC, reduce circuit drive loss, reduce operating costs.

• 1). Original “energy-saving screen” technology, the temperature is 30-50% less than the conventional screen, effective control of temperature rise, more stable operation; super heat dissipation, small power loss, low heat, low temperature rises of the screen, long life, good display effect.

• 2). Using 2.8V + 3.8V dual-channel power supply, saving half the number of power supplies, reducing the failure rate.

• 3). Low power consumption, power saving about 30-50%, energy efficient drive IC, reduce the loss of drive circuit, reduce operating costs.

• 4). Low heat, natural heat dissipation without air conditioning, working zero noise more energy efficient, extend the life of the display.

• 5). Cold light source high brightness, better meet the high reliability requirements of outdoor applications.

• 6). Ultra-high refresh display, fast frame change speed, eliminate ghosting without trailing, low brightness and high gray non-destructive technology, solve industry problems.

• 7). CNC finishing magnesium aluminum cabinet, lighter than the traditional iron cabinet 22Kg/㎡, lighter than the die-casting aluminum 8Kg/㎡.

• 8). Galvanized latch design, easy front and rear maintenance, thin box, the whole screen thickness is small, can be free of channel free air conditioning installation.

• 9). Cold light source high brightness, ultra-high refresh, eliminate ghosting without trailing, the picture is fresher and more delicate, high fidelity.

• 10). Fully sealed magnesium aluminum cabinet design, waterproof, dustproof, anti-corrosion, flame retardant, anti-ultraviolet, V0 fire code, protection level up to IP65, can withstand 130 degrees high temperature test, can be placed under 3 meters pool immersion and normal work; extreme cold, heat, high UV, and other harsher environments, adhere to the non-deformation, non-aging, no leakage, no fire.

The actual measured data show that: the same specification products, the same brightness, the screen body temperature of the common cloud led display than the conventional common led display products screen body temperature is more than 20 degrees lower, power consumption than the conventional common led display products more than 50% lower.

According to statistics, the global annual production of led display more than 3.5 million square meters, according to the power consumption of 300 watts per square calculation, the annual power consumption of 1.75 billion kilowatts of electricity. This does not count the electricity consumed in the production process. If all adopt common cathode led display, it will save at least 725 million kilowatts of electricity for the society every year. The future common cathode led display can become today’s led display market can really bring great economic benefits and value for the customer’s competent competition!

5. Application Occasions:

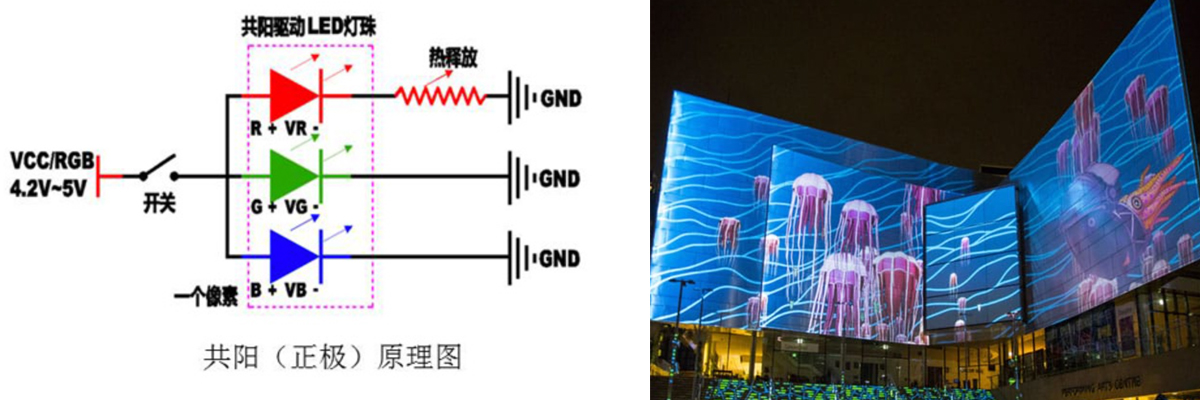

At present, common cathode technology is more often applied to outdoor led displays, because the size of outdoor led displays is generally larger, common cathode technology applied to large size displays will be more valuable.

In addition to the use of rgb common cathode technology to reduce power consumption, for indoor small pitch led display, its internal can also use the original balanced variable current synchronous display technology, to avoid the traditional constant current IC pulse (duty cycle) display caused by frequent adjustment of MOS tube tangent, resulting in LED / PCB power supply and other problems generated a lot of heat.

At the same time, the use of very small current starting gray, high efficiency, low brightness and high gray, high contrast, less heat, large scan number, gray scale fine performance and other multiple display mechanisms together, the screen in normal use state requires a very low drive current (1.2mA or less), power consumption of about 60W/m². Using this way of small pitch led display, its energy-saving effect can reach 60%.

6. Common Cathode LED Display to Save Money:

• 1). Save electricity, save operating costs: accurate power supply to reduce led display power loss, reduce operating costs.

• 2). Save device input cost: low heat temperature rise can also save the air conditioning, fans, and other cooling equipment.

• 3). Save maintenance and repair costs: the subsequent fully enclosed die-casting aluminum chassis, the components are maintained one by one, making the led display life is about 2 times that of ordinary screens.

7. Common Cathode Can Make Display Energy-saving Up to 75%:

The common cathode power supply technology can separate the red, green, and blue lamp beads of led display and supply power to them separately and precisely, so that each lamp bead can work under the best current voltage, thus improving the utilization of electric power and reducing the loss of electric power.

In addition, the common cathode power supply method is the current is first through the led beads, and then to the cathode terminal of the driver IC, reducing the forward voltage drop, further reducing the loss of power in the process of circulation. LED display using common cathode technology can indeed reduce power consumption, but how much power consumption can be reduced, we say the common cathode energy saving 75% is how to come?

• 1). In fact, not all led displays using rgb common cathode technology can reduce power consumption to 75%, the actual power consumption should be reduced in the range of 30%-75%. Here, I will use the conventional P10 aluminum module led display and common cathode P10 aluminum module led display to do a comparison:

The maximum power consumption of conventional standard P10 aluminum module led display is 900W/m², the average power consumption is 300W/m², and the white balance brightness is 6000cd/m².

The maximum power consumption of common cathode P10 aluminum module led display is 350W/m², the average power consumption is 118W/m², the brightness is 9500cd/m².

We use the average power consumption to calculate: (118W/m²-300W/m²)/300W/m²=60.67%, which means that the top configuration version of the common cloud P10 aluminum module led display than the conventional standard P10 aluminum module led display power consumption is reduced by 60.67%.

| Aluminum LED Module | Standard Model-P10 (FA10) | Common cathode configuration-P10 (FA10-C3) | ||

| P10 (FA10-C3) | Saved power consumption (W/m²) | Power saving ratio | ||

| White balance brightness (nits) | 6000cd/m² | 9500cd/m² | / | / |

| Maximum power consumption (W/m²) | 900.00 | 350.00 | / | / |

| Average power consumption (W/m²) | 300.00 | 118.00 | 182 | 60.67% |

• 2). However, look more closely at the above table we can find that the brightness of the conventional standard P10 aluminum module led display is 6000cd/m², while the brightness of the common cloud P10 aluminum module led display is 9500cd/m², common cloud technology not only makes the power consumption of the P10 aluminum module led display reduced by 60.67%, at the same time, the brightness also increased by 58.3% (9500 -6000)/6000=58.3%.

The same specification of led display, the higher the brightness, the greater the power consumption should be, but the common cathode technology has changed this result.

Here, we convert the brightness of the common cathode P10 aluminum module (9500cd/m²) into the same brightness as the conventional standard P10 aluminum module led display (6000cd/m²), and then compare their power consumption.

For the common cathode P10 aluminum module led display, when its brightness is 9500cd/m², the average power consumption is 118W/m²; then, its brightness is also 6000cd/m², the average power consumption should be 74.53W/m² [(6000*118)/9500=74.53], the same can be calculated when the brightness is 6000cd/m², the maximum The power consumption is 223.59W/m².

| Aluminum LED Module | Standard Model-P10 (FA10) | Common cathode configuration-P10 (FA10-C3) | ||

| P10 (FA10-C3) | Saved power consumption (W/m²) | Power saving ratio | ||

| White balance brightness (nits) | 6000cd/m² | 6000cd/m² | / | / |

| Maximum power consumption (W/m²) | 900.00 | 223.59 | / | / |

| Average power consumption (W/m²) | 300.00 | 74.53 | 225.47 | 75.16% |

• 3). So, we still use the average power consumption calculation:

(74.5W/m²-300W/m²)/300W/m²=75.16%, which means that under the same brightness (6000cd/m²), the power consumption of the common cathode P10 led display is 75.16% lower than the conventional standard configuration led display.

Here it should be noted that these conversions are based on mathematical calculations, in the actual operation or adjustment process, will also be affected by current, voltage, resistance and other factors. But this does not affect the conclusion we have argued: the common cathode technology makes the led display energy-saving effect of up to 75%.

8. For Common Cathode Energy-saving Screen Discussion:

- 1). The Energy-saving Level of Common Cathode

If the common sun with 5V power supply, red led with 2.8V when common cathode, other unchanged, and red led current in the total current accounted for 40%, then save 40% * (5-2.8)/5 = 17.6%. If the red LED current is 50% of the total current, the savings is 50%*(5-2.8)/5=22%.

A. Pengrui Shao, Technical Director of Kinglight:

The energy saving of common cathode, mainly the original single power control to dual power control, the red drive voltage from about 4v to about 3v, the red working voltage dropped about 30%, so to be exact, the common cathode red power dropped about 30%, and there is about 10-15% integrated.

B. Cai Zongda, Director of Marketing Department of MBI:

Common cathode advantage is to reduce the red led supply voltage to reduce system power consumption, but other ways to reduce system power consumption, the use of common sun can also be achieved. If the goal is to reduce system power consumption and heat generation, you can also use co-opt LEDs, but add other energy-saving designs to maximize the goal.

C. ROE chief engineer Meng Linke:

LED display is gradually entering the maturity stage, the product requirements are getting higher and higher, especially in reliability, service life and display consistency have higher demands. LED is a temperature-sensitive components, with the rise of temperature, light decay becomes larger, color deviation, thermal expansion and contraction become more serious, affecting the airtightness of led, common cathode technology to reduce the temperature of the screen body, a good solution to the above problems, while electronic components in a relatively low temperature with higher reliability, longer life. In terms of temperature reduction, common cathode technology is undoubtedly the trend in the mid- to high-end market.

In the solid-state products, because they are in use for a long time, energy saving can let customers save costs, and in the long run is more cost-effective.

- 2). The Most Common Array (array) Architecture Is Standard?

Although common sun is more suitable for the moment, but common cathode in reducing the red led supply voltage is better than common sun. So, what is the core supply technology? From the feedback and communication, we found that the most mentioned are these key words: PLL (phase-locked loop), PWM (pulse width modulation engine), dynamic energy saving, high gray scale (16bit). And PLL, PWM is the, involving patent doubts Array (array) architecture of the six-key links in the two. However, for the question of whether the array is necessary, each family has its own view.

A. Yichen Zhao, Chairman of Rising Sun:

Agree that common cathode technology is currently better practice is to use Array (array) architecture, but is not the only architecture, the specific or according to the technical requirements of display products and market positioning decision. Sun and moon into not only provide array type, but also provide discrete.

Common cathode driver IC on-chip PWM is necessary, this is because common cathode in addition to energy saving, reduce the temperature of led beads is the core demand! If you do not use PWM technology, you will have to meet the brightness requirements by increasing the drive current of the led beads, thus making the working power consumption of the led beads increase significantly, offsetting the benefits brought by the common cathode. But common cathode driver IC on-chip PLL is not necessary.

B. Multiple display factory technical director:

Common cathode has in the layout, but not yet vigorously promoted. The main reason for the slow advancement of common cathode technology is the high cost of production, based on the original supply chain collaboration, common cathode requires customization of the chip, packaging, PCB and other ends of the industry chain, the cost is higher. But once the volume is up, the production is standardized rather than customized, especially if there are terminal manufacturers to support the vigorous upward push, common cathode technology is the opportunity to promote faster.

In this new trend, the launch of the industry’s cutting-edge common cathode common anode combination of programs to save energy in the case of ultra-low temperature, commonly known as cold screen, efficient solution to the problem of heat dissipation. Outdoor S10 energy-saving common cathode screen series and conventional ordinary screen comparison, the advantages have: 1. high brightness 7000CD, 2. high efficiency and energy saving 50%, 3. flatness consistent, 4. good heat dissipation, long life, 5. high-cost performance, and other five advantages.

- 3). Accurate Power Supply and Real Energy Saving

Common cathode products use precise power supply control technology, based on the different photoelectric characteristics of the led red, green and blue, with the intelligent IC display control system and independent private mode, for the led and drive circuit to accurately allocate different voltage, so that the product power consumption relative to similar products on the market power saving of about 40%!

According to the current national policy and the development needs of led display, energy-saving products are the general trend, and the layout of enterprises is also no excuse for common cathode energy saving. However, enterprises should also objectively look at the difficulty of entering the industry, whether the industry is mature, whether the production cost can afford, whether the return cycle can afford, according to their own situation to weigh, objective analysis, choose the most suitable for their own development path.

9. The Difficulty of Common Cathode Energy-saving Screen:

LED display industry from time to time to launch new technologies new products, which is conducive to pulling new demand. Common cathode this new technology has a better energy-saving effect, this technology responds to the national policy of emission reduction, but also to meet the end-user demand for energy saving, is expected to turn the new water in the stable development of the led display industry, so when the technology is open, a crowd of led display companies tend to rush, have entered the game, research and development of related products, the common cathode energy saving pushed to the forefront of the wind.

Under such a great heat, the common cathode energy saving into the industry seems to be inevitable, but in fact there are many obstacles, so that led display manufacturers must face up to. Common Yin energy saving want to really enter the industry, but also from the solution of these difficulties.

• 1). Difficult to escape from the shadow of the patent has not receded

Whether from the level of energy saving and emission reduction, or from the perspective of pulling the led display industry new demand, common cathode is a favorable technology. Although the led display is becoming more and more sophisticated, but along with the development of the industry’s high-power consumption has been the industry’s pain point, the opening of this technology, to promote the development of the led display industry in the direction of energy saving plays an important role.

But the patent of this technology is abroad, China has and only one enterprise has been authorized, and a long time does not open to the public, until nearly a year to open to the public. Although the technology has been open, but also limited to domestic, once the product is sold overseas, there is a high probability of copyright patent litigation issues.

Most led display companies are export-oriented enterprises, products are sold around the world, companies want to lay out the common Yin energy-saving, then the common Yin energy-saving overseas market needs to be temporarily abandoned. On the domestic side, many enterprises to seek new development opportunities, have laid out the common cathode energy saving, the market competition is relatively fierce, so the enterprise to speed and quality of both products, to seize the market.

Although the patent is very important at home and abroad but led display manufacturers also need to know how to protect their rights. Actively look for the common cathode technology has been publicly available information and related technology, looking for favorable conditions for the use of common cathode technology to improve the degree of use of common cathode technology. Of course, there is more than one way to save energy, the need for the hard work of the led display manufacturers, efforts to research and development, looking forward to the next energy-saving technology, mastered in the hands of the country.

• 2). Common cathode energy-saving support is not perfect, the main battlefield of common cathode energy saving lies in small pitch

Common cathode energy-saving technology through dual power control, the voltage from about 4V down to about 3V, effectively will reduce the red-light power of about 30%, reducing the integrated power consumption of about 10-15%. Common sun technology led display since its birth, the power supply is used in common sun technology, due to high power consumption, as well as the end-user and the country’s demand for energy saving, so the led display has also been expanding the energy-saving effect of common sun technology.

After years of development and improvement, the energy-saving effect of the common sun technology can also achieve quite good results, and the current market is still mainly to feed the technology. Although the common yin energy-saving technology is good, but because the “age” is still young, the corresponding industry chain digestion support has not been perfected, temporarily cannot be mass production, so the cost competitiveness is low. In the face of such a situation, it is necessary to develop the layout of the whole industry and promote together to accelerate the rapid maturation of the common yin energy-saving products.

In addition, from the perspective of the common cathode energy-saving products released by the enterprises, common cathode energy-saving products with COB packaging technology, mostly used in the field of small point pitch display. From the technical level, the common cathode energy-saving small current precision and consistency, low gray and high brush processing and other key technologies are more applicable to small-pitch led display. Therefore, combined with the future development trend of ultra-high-definition display, in the future, the layout of smaller point pitch common cathode energy-saving products is the best policy.

10. The Development Trend of Common Cathode Technology:

With the common cathode led display technology related to supporting such as led, power supply, driver IC, etc., is not yet as mature as the common anode led industry chain, coupled with the current series of common cathode IC is not complete, the overall volume is not large, while the common anode still occupies 80% of the market.

Common cathode technology is currently slow to promote the main reason is the high cost of consumption, based on the original supply chain collaboration, common cathode needs chip, packaging, PCB, and other ends of the industry chain customization with a higher cost.

In this period of high energy-saving calls, common cathode configuration led display has become the support of this industry chase. But to complete a greater sense of the full implementation and application, there is still a long way to go, which requires the joint efforts of the entire industry. As the trend of energy-saving development of the common cathode led display screen, touching the use of electricity and operating costs, so energy saving is related to the interests of the led display operators, but also to the use of social energy.

From the current situation, the common cathode led energy-saving display does not increase the cost too much than the conventional display, and in the later use will save money, worthy of the market esteem.

11. What Are the Opportunities and Challenges?

Energy saving is the direction that any industry is striving for. In addition to the market demand, it also meets the current government requirements of “greening” and “energy saving and emission reduction”. This also brings a new direction to the development of the industry and injects new momentum. In line with the trend of the times and the birth of the led common cathode energy-saving screen what is the “magic” so that screen enterprises scrambling to layout? And what challenges are faced?

• 1). Common cathode technology advantages into a new blue sea of competition manufacturers

We know that the common cathode led display than the common anode led display power consumption is much lower, and the common cathode led display than the conventional common anode led display heat is much lower. In addition to technical parameters make the common cloud led display and conventional display is different, common cloud led display to the operator to direct to the significant advantages is to save electricity, save operating costs, to truly achieve accurate power supply to reduce led display power loss, reduce operating costs.

On the other hand, save installation input costs, low heat temperature rise can also save air conditioning, fans, and other cooling equipment, and at the same time also save maintenance and repair costs, the subsequent fully enclosed die-casting aluminum chassis, the components are protected one by one, making the led display life is about 2 times the ordinary screen. LED display screen body temperature is too high and power consumption is too large, has been the impact of led display product life Key factors, and the common cathode led display can precisely solve these two problems well.

• 2). Common cathode technology industry chain has not yet matured a long way to go

In this era of high energy saving, the emergence of common cathode led display and inevitably become the support of this industry chase. But to achieve a greater sense of comprehensive promotion and application, there is still a long way to go, which requires the joint efforts of the entire industry.

Common cathode led display involves the use of electricity and operating costs, so energy saving is related to the interests of the led display operators, but also to the use of national energy. From the current situation, the common cathode led energy-saving display does not increase the cost too much than the conventional display, and in the later use of the cost savings, by the market’s esteem.

As the development trend of energy-saving common cathode led display, is bound to be a variety of indicators under the comprehensive results, led lamp beads, driver IC, switching power supply, product power consumption design, intelligent energy-saving system design and structure of energy-saving design and other related to the energy-saving effect, can be said to cover the led display from the led display factory, driver IC factory to the led packaging factory and other led display industry upstream and downstream, so also need the cooperation of the whole industry.

Previously, there are also industry insider’s analysis, common cathode led display technology related to supporting such as led, power supply, driver IC, etc. is not as mature as the common anode led industry chain, if the goal is to reduce system power consumption and heat, you can also use common anode led, but join other energy-saving design together to maximize the goal.

For the time being, common cathode can be more energy efficient than common anode. However, the common cathode has just begun, not to say that it has solved the big problem, now only can realize the common cathode mass production. Relatively mature later, theoretically can better deal with ghost caterpillars, energy saving, including standby energy consumption.

Common cathode IC is currently not a full series, the overall volume is not large, common Yang still occupies 80% of the market. Common cathode technology is currently slow to promote the main reason is the high cost of production, based on the original supply chain collaboration, common cathode needs chip, packaging, PCB and other industry chain customization with each end, the cost is higher. Once mass production is achieved, production standardization rather than customization, especially if there are terminal manufacturers to support the vigorous upward push, common cathode technology is the opportunity to promote faster.

• 3). The patent problem is an obstacle to the development of common cathode technology

Patent problems have hindered the development of common cathode technology to a certain extent, which is probably why common anode still occupies the mainstream market today. But with the development of led display to the direction of miniaturization, energy saving, and temperature reduction needs will become more and more obvious, then the common cathode technology involved in the patent problem is there a way to solve it?

The relevant survey shows that from 1999 to the present, the led display driver IC field related patents about 3997. Relevant patents in this field began to accumulate and grow significantly in number in 2002 and entered a phase of rapid growth from 2010 to 2016. In the field of common cathode architecture, the main applicants currently include U.S. Silicon Core, Guangzhou Silicon Core Electronics, Hangzhou Vision Core, and Fuzhou Fuchai Silicon Microelectronics.

Among them, Silicon Core USA and Guangzhou Silicon Core Electronics are the main patent applicants in this field, which started to file patent applications in both China and the US as early as 2011. In 2013 and 2015, they passed three Chinese patents including CN102855841B main case; in 2015, they passed three US patents including US8963810 main case, mainly covering led display systems including led arrays and led driver circuits.

The current to common, more advantageous Array (array) architecture core patents are a display manufacturer that does not sell the drive IC – the United States Silicon Core mastered, the international patent is very important, common architecture way was applied for by others and not external, the big industry cannot use, if the patent is a monopoly, in many projects will be hindered, is not conducive to the overall development of the industry.

Industry legal experts also gave corresponding advice, for the core patent in the hands of an enterprise this case, industry counterparts should first analyze the core patent corresponds to the strength of existing products, and in the published patents and has been published in the relevant literature, to find a good technology related to pre-patent cases and has been published in the literature, the future can be invalidated each other’s patents or limit the scope of their patents, as a bargaining chip in licensing negotiations.

• 4). It is certain that in the future, the common cathode led display will be an important bargaining chip for the competition.

Common cathode energy-saving led display with its superior low heat, low power, low loss, cost savings and other advantages to attract many manufacturers to compete for, common cathode energy-saving technology is a trend, but cannot be used as a gimmick of enterprise competition, so if you want to achieve large-scale mass production of China, there are still facing many problems.

Common cathode led display technology innovation, it is impossible to rely only on the terminal display manufacturers to complete independently, but the need for industry chain upstream and downstream manufacturers to cooperate, and secondly, in this process also need to avoid the risk of patents. As the saying goes, “The future is bright, the road is winding.” With the further development of the market, screen enterprises will be in the common cathode led display this professional segment, whether it is research and development, production or market and other aspects to bring us unlimited surprises.

12. Summary:

Reduce the power consumption of led display, improve the performance of the display, has always been the industry is committed to the direction of research, major enterprises in the field of energy saving led display invested a lot of manpower, material resources, research, and development of common cathode energy-saving technology.

Energy saving and environmental protection is the future direction of the led display, research and development and production of high-performance, low-power products to truly solve the problem for customers, but also to design the led display to easy maintenance, so that the display can be stable long-term operation. With the production technology of led display more and more mature, the future development of led display will revolve around energy saving and low power consumption, easy maintenance, and to achieve more personalized requirements of the direction of development.

About LEDSINO

As a professional LED Display Manufacturer, LEDSINO provides reliable products, comprehensive services and creative solutions.Since establishment, our team has been continuously innovating. Our Rental LED Display,LED Poster, Stage LED Screen, Flexible LED Display,Transparent LED Display, Church LED Wall, Concert LED Screen, LED Drape Screen, Nationstar LED Screen, LED Display Ball, Stadium LED Screens have the most advanced technology and forward-looking design in the present market.

For more information about LEDSINO, please follow us on Youtube, Twitter, Facebook, Instagram or Linkedin!

Related Products Or Cases