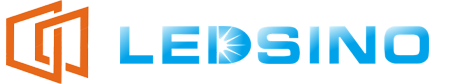

You’ve probably noticed some jaw-dropping LED displays in malls, on buildings, or at events and wondered: “How do they make those screens curve and twist like that?” What you witnessed is flexible led display technology in action.

What Is A Flexible LED Display?

Flexible LED screen displays are revolutionary displays that are designed to be bent, curved or twisted and yet do not distort the image. These differ from conventional fixed frameworks in that they utilize flexible materials such as polyimide films or thin dielectric boards.

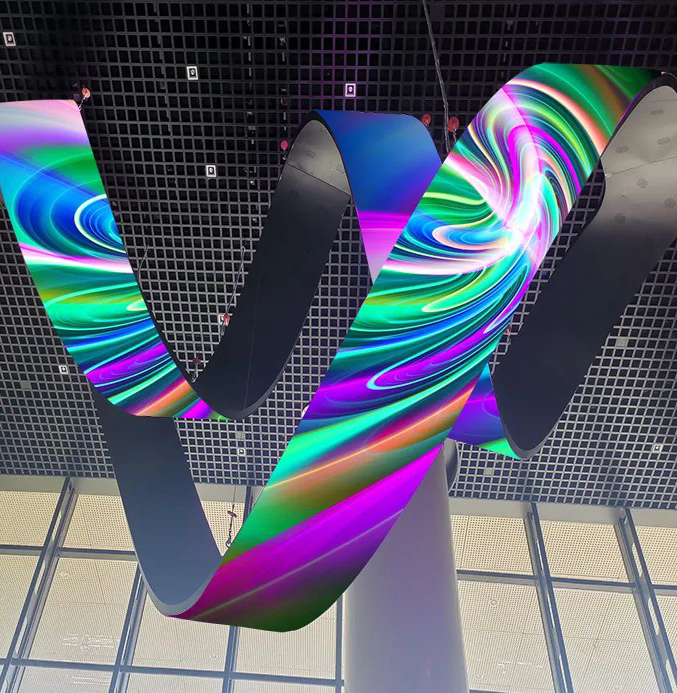

This enables them to attach to unique shapes including columns, spheres, and even apparel. It will also have ultra-thin modules and lightweight components as well as improved durability that allows for a hassle-free integration into creative solutions.

The primary reason flexible led display screen displays are different is flexibility. For instance, in the retail context they employ them to produce complex, curved ad display surfaces with which customers engage. Another important aspect found in these screens is high pixel technology that makes the graphics bright and clear as it consumes little power.

From engaging art installations to dynamic architectural designs, there is no denying that led flex screen displays are redefining the art of visual communication. Their potential is almost endless and that’s why they are the preferred solution for many industries that seek to mesmerize their audiences with the latest technologies.

How Does a Flexible LED Display Work?

Flexible led screen display displays operate through a combination of advanced pixel technology, lightweight circuit design, and bendable materials. At the core of these splashes are LED chips that light up when connected with a power source. They are installed into flexible printed circuit boards (PCBs)––Polyimide or any other material depending on the flexibility the designer needs to create in the display, making it possible for the screen to continue to work properly even if bent or twisted.

Each pixel uses red green and blue (RGB) LED diodes, meaning that it can produce millions of colors. These diodes are driven by driver ICs wherein the brightness, color, and the rates of refreshment are all regulated. The flexible substrate serves as a backing to the LEDs whilst providing the necessary rigidity required to ensure that there is conductivity despite the movement.

For instance, a led flexible display sign with 4mm pixel pitch, known to be used in interior advertising and marketing, holds approximately 62,500 LEDs per square meter, hence the ability to display clear images when people are closer. The flexibility of the display results from the modular approach in which thin and small LED panels are connected to form continuous strips that can conform to complex shapes.

Together, flexible led technologies allow uses in creative fields, including 360-degree immersive domes and wearable technology. Flexible LED displays bring out the best of both worlds with high refresh rates and low power usage, making them distinctive performers of dynamic visual solutions.

Materials Used in Flexible LED Displays

The functionality and versatility depends on the type of the materials that is used in the flexible led panel displays. Flexible LED displays are unique from other LED displays because they use superior materials to ensure the necessary flexibility and durability.

Flexible PCB Boards

The main component of any flexible flex led display is a flexible printed circuit board, usually based on polyimide or polyester. This material lets the board flex without breaking while providing a high degree of heat resistance and insulation from electricity.

Some of the main materials used include Polyimide, which is capable of withstanding temperatures of up to 400° C, for example. The combination of polyimide films and thin dielectric boards gives flexible LED screens capabilities to adapt to different uses including led panel flex which addresses the need to embed dynamic see-through images on glass surfaces.

LED Diodes

The primary components of these displays are the RGB LED diodes; they illuminate and provide colour. For high efficiency and high brightness, devices use high-performance semiconductors of gallium nitride (GaN) and indium gallium nitride (InGaN). In particular, these diodes are very small with sizes from 1mm to 3mm in diameter area hence ideal for intricate designs.

Protective Coatings

To protect the LEDs and circuits from dust, moisture and physical shocks epoxy resin or silicone coating about 0.2mm thickness is applied. These coatings not only increase the durability of an unheated display, but also do not affect its sight clarity.

Adhesive Layers

Flexible displays usually make use of some kind of adhesive in order to join the layers while allowing them to move. For instance, many of the connections in the present day flexible display use silicone adhesives so that even though they stress or twist, the layers will not separate.

Driver ICs and Connectors

Integrated circuits, such as driver ICs are used in controlling brightness and refresh rates. These ICs are connected to the diodes via flexible connectors, whose properties remain constant on curved or irregular surfaces.

Manufacturing Process of Flexible LED Displays

Flexible transparent led screen displays are produced through several precise procedures to guarantee the foldable led screen displays are flexible and perform well.

The process with flexible PCB starts with creating the base of the flexible PCB, often copper is deposited on polyimide or polyester. The copper is patterned into networks where the LEDs are to be located, to carry the electrical circuits.

Then by employing surface-mount technology (SMT), thousands of small LED diodes are mounted on the circuit board. This operation is done by robotic arms to avoid distorted placing particularly for the pixel pitches that can be as small as 1mm.

The driver ICs and other electronic components are interfaced to the circuit. The board is bendable, but in order to ensure that there is provision for electric connections, flexible connectors are used.

Subsequently, an additional layer of clear resin or a coating is applied to the ultra thin flexible led screen for protection purposes. This step is important because it gives the display the ability to shield itself from any environmental influences while retaining flexibility.

The panels are then tested with bend test (up to 100,000 cycles), brightness calibration and color consistency. At last, each component is connected as a single block prepared for installation onto curved or complex-shaped surfaces. The final device produces a flexible programmable flexible led display ready for placement into challenging surfaces.

Applications of Flexible LED Displays

Flexible LED displays have revolutionized multiple industries due to their versatility and creative potential. Here are some notable applications:

- Advertising and Retail: These displays are applied in retail facilities such as in flexible led sign displays to draw attention and increase the level of interest of the consumers. Organizations evaluating innovative advertising solutions analyze performance alongside durability and flexible led screen price relationships to determine effective cost-to-quality ratios. For example, Nike has installed flexible displays in its New York store that can change in accordance with the different campaigns.

- Wearable Technology: Stretchable LED displays are gradually finding uses in wearable devices such as Smart watches, fitness trackers and clothing. A good example to exemplify this is the LG Flexible OLED Watch- the display curve is for the wrist without affecting functionality.

- Education and Museums: Spherical and curved LED displays are applied to planetariums, museums, and science centers to present informational lessons. The American Museum of Natural History uses fluid flexible led panel screens in its modern astrophysics showcases.

Advantages of Flexible LED Displays

Flexible LED displays offer several benefits that set them apart from traditional flat-panel displays:

- Lightweight and Compact: led wall flexible PCBs and compact devices contribute to the decreased weight that is beneficial especially when installing the HV periphery devices. For instance, a 10m² flexible LED screen usually has a weight of 30% less than the traditional screen.

- Adaptability: Designing is made flexible because the material can bend and be adjusted to curved or irregular surfaces. This flexibility is especially valuable in works created for environments and large structures – in sculptures and reliefs.

- Energy Efficiency: Today’s LED diodes are energy-efficient when compared to older technologies, and provide better visibility. An adaptive and relatively small bendable led screen display, which can reach a brightness of 2,000 nits, can function at 50W/m2.

- High Resolution: Flexible displays have a minimum pixel pitch of 1.5mm, which allows them to provide good pictures when viewed closely—an important factor for potential retail and exhibitions.

- Durability: A combination of both protective coatings and rigid materials make sure flexible led module solutions are able to bend and twist while at the same time being able to withstand environmental stress and can work up to 100,000 hours.

Conclusion

Flexible LED display solutions represent the future of visual technology. Whether it is in advertising, wearable technology devices, they are revolutionizing the way we engage with digital media. Given present day developments, flexible led screen panel innovation continues to push the boundaries.

Enter the digital world with our advanced display technologies.