Selecting an appropriate display becomes difficult. To make this choice you need to know both the basic components of SMD and COB displays. Our guide examines these technologies to show you which one meets your needs.

What Are SMD And COB Displays?

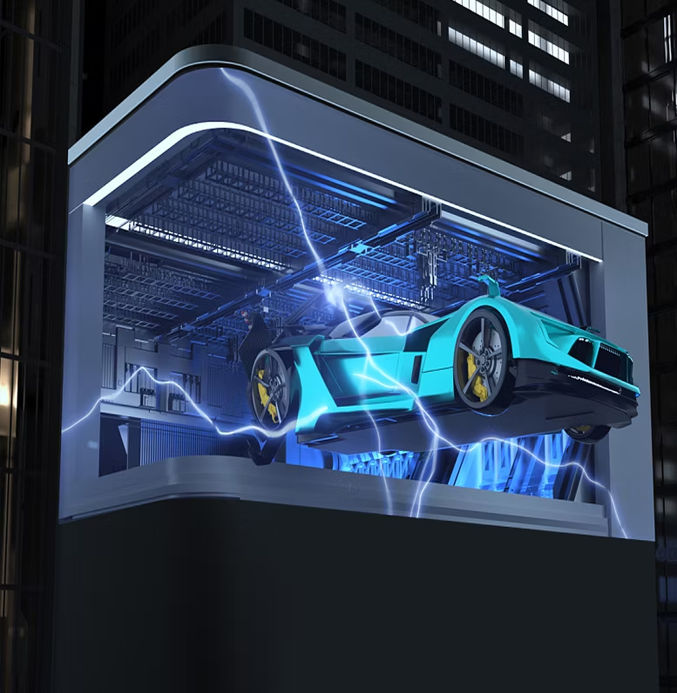

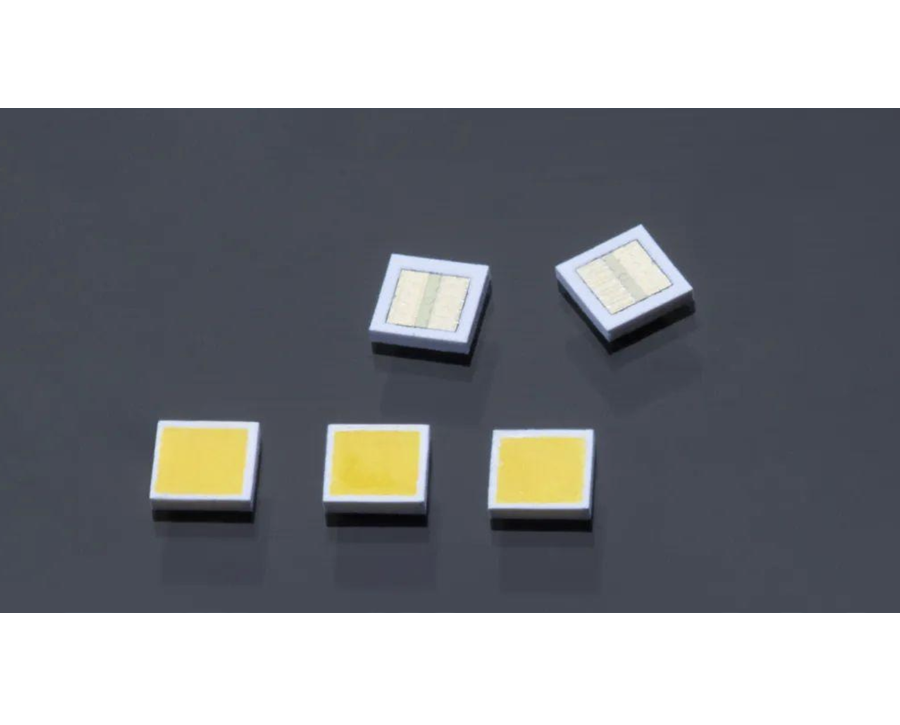

SMD refers to LED displays which place light-emitting diodes directly onto circuit board surfaces. The smd led unit consists of three small diodes arranged in a pixel grid, red, green, and blue. The placed diodes form a small design that lets us control light output and color options precisely.

With COB displays LEDs attach directly to substrates through a different manufacturing process. A collection of LED chips connects directly to a base element to create one connectable unit. The LED chips sit very close together to provide a smooth surface that conducts heat more effectively. The system creates a clear uniform light effect without visible pixelation.

Even though both technologies deliver quality images they use fundamentally different approaches in design and operation.

Key Differences Between SMD And COB Displays

Size And Design

SMD screens have a compact shape because their display modules use small LED diodes. The technology suits displays that need extreme detail and special designs for digital signage. Since each LED chip on a COB display is closely placed together they create a smoother display surface. Small pitch requirements work best with SMD displays but COB setups deliver uniform results on large surfaces.

The Displays Deliver Even Light Distribution and Strong Color Consistency

SMD screens display bright quality images perfectly for detailed advertising purposes. The unique placement of COB components ensures that screens produce consistent bright levels and balanced colors across their entire surface.

These Display Options Last Longer While Also Dispelling Heat Effectively

COB technology shows superior resistance to breakdown because of its unique design. The screen design improves heat removal to keep the display cooler and work longer. SMD displays provide excellent durability but need reliable cooling technology particularly for strong usage such as a p10 smd outdoor led display.

Viewing Angle And Pixel Pitch

Users see distinct visuals without distortion at any angle when using SMD displays. COB displays give exceptional results for module p5 full color outdoor setups because they produce a smooth picture without visible pixels across narrow viewing angles.

Production Steps And Expenses

The manufacturing of SMD displays needs LED placement on each circuit board part and raises production expenses for intricate designs. COB displays deliver the lowest product costs across larger display installations because their chip bonding process stays straightforward.

Advantages And Disadvantages Of SMD Displays

Advantages:

High Brightness and Clarity: SMD displays produce very bright visuals combined with vivid colors which work perfectly for both inside and outside display applications.

Wide Viewing Angle: SMD screens show content clearly across wide viewing areas each direction.

Energy Efficiency: SMD display technology needs less power than LED displays to work so businesses pay lower energy expenses.

Compact Design: Components in SMD technology make possible thinner and lighter display structures.

High Resolution: They achieve better picture quality than traditional displays through their construction.

Durability: They stay strong under extreme temperature and wet conditions.

Flexibility: Our screens adapt to any curved or custom shape and fit so business owners get design flexibility.

Disadvantages:

Higher Cost: SMD displays cost more to produce and put in place than regular display options.

Complex Repairs: Breaking SMD components needs professional tools that cost a lot of money to repair.

Heat Generation: The display’s high brightness setting produces excessive heat needing special cooling systems to prevent damage.

Limited Outdoor Use: The display screen endures well but weather factors like heavy rainfall or direct sun exposure decrease its working ability.

Fragility: Because of their small size SMD components break easily during handling and moving.

Power Supply Requirements: Display devices requiring SMD technology need consistent voltage power to function normally and installation becomes more complex.

Advantages And Disadvantages Of COB Displays

Advantages:

Enhanced Durability: COB technology gives displays better protection against impact damage plus water and dust because all elements attach directly to one board.

High Brightness: These displays deliver superior light output that works well in all environments including closed spaces and open areas.

Energy Efficiency: COB technology needs less power to run screen displays than standard LED screens do.

Improved Heat Dissipation: COB displays release heat better so they run cooler and last longer than traditional screens.

Seamless Display: Their compact design closes LED gaps to show visually perfect light patterns.

Lightweight and Compact: COB displays are both lighter and more portable because their size makes installation simpler and allows better movement.

High Reliability: By continuing to build components at their most basic design they stay reliable even through many years of service.

Disadvantages:

Higher Initial Cost: Organic Light-Emitting Diodes (OLEDs) for displays will cost you more than regular Flat Panel Displays to set up.

Lower Pixel Density: The pixel density of COB displays remains lower than for SMD displays which makes close-up viewing details appear blurry.

Complex Repair Process: Fixing COB displays proves tough because the integrated chip runs throughout the screen.

Limited Customization: COB displays lack the design flexibility for custom unique shapes and curved display configurations.

Smaller Viewing Angle: The display’s field of view may reduce slightly due to its construction.

Sensitive to Voltage Variations: Display performance or properties decline when you feed the device with uneven power.

Applications Of Smd And Cob Displays

Retail And Advertisements

Businesses use SMD displays to show changing images in retail shops and advertising spaces. Their high-quality design with vivid colors and details serves advertising needs well on smd screen platforms.

Outdoor Billboards

The two display technologies work well for outdoor deployments. A dip led module with SMD technology delivers brighter display output than the heavy-duty COB display when exposed to extreme weather.

Indoor Video Walls

SMD displays deliver sharp pictures to indoor spaces while COB displays keep visual quality consistent for close viewing areas.

Stadiums And Events

Large capacity venues choose COB displays because their technology brings stability combined with bigger show screens. SMD displays deliver great brightness and clear visuals at small event spaces alongside their peers.

How To Choose Between SMD And Cob Displays

Assess Your Project Needs

An smd led video wall delivers precise images with adjustable brightness levels. For scenes that need continuous large-screen display performance COB technology proves better.

Consider The Environment

SMD displays handle both indoor and outdoor conditions yet require controlled environments to reach their full potential whereas COB displays work best in controlled environments.

Budget

COB panels provide lower purchasing costs when you need to outfit many large screen displays.

Maintenance

When you need basic display care opt for SMD tech especially when doing p5 smd projects.

Viewing Distance

COB displays create uniform visuals at short viewing distances. When users need clear vision across long distances SMD display technology remains superior.

Conclusion

Different applications call for either COB or SMD display technology. Your choice between COB and other display types depends solely on project needs and financial resources. Learning display technologies helps you pick the perfect system that matches your needs by 2025.

Enter the digital world with our advanced display technologies.